A Tale of Two WMS Implementations: Why Two Consulting Firms Can Be Better Than One

Big warehouse programs don’t stumble on vision-they stumble when complexity across client-side leadership and vendor-side execution isn’t coordinated. Blue Yonder WMS affects people, process, data, and tech. Getting it right means combining a partner who champions your interests on the client side with a partner who brings deep vendor-side operational and integration expertise. That’s the strength of Alpine Supply Chain Solutions and Longbow Advantage working as one team: clear ownership, complementary skills, and outcomes that hold after go-live.

Together, these teams bring more than 400 successful WMS projects led by seasoned practitioners. As Longbow CEO Ryan Uhlenkamp puts it, warehouse leaders “don’t just buy software, they buy outcomes.” Alpine’s Michael Wohlwend echoes that alignment: the partnership assembles one of the industry’s deepest implementation benches, ready to deliver value quickly and consistently.

All organizations can benefit from this because you’re getting both lenses that matter: a client-side advocate ensuring the program serves your business goals, and a vendor-side specialist ensuring the system is built, integrated, and stabilized the right way.

A Proven End-to-End WMS Implementation Framework

Our joint approach follows a practical, multi-step path that protects day-to-day operations while your system takes shape:

- Discovery – Align stakeholders, assess current workflows and data, and clarify business objectives.

- Solution Design – Configure Blue Yonder WMS to real-world processes with a pragmatic “to-be” state.

- Build & Integration – Stand up environments, ready data, and connect adjacent systems.

- Implementation & Data Migration – Execute the plan with disciplined cutover management.

- Testing & Go-Live – Validate end-to-end flows, stabilize performance, and prepare the floor for day one.

- SOPs, Work Instructions & OCM – Equip teams with usable documentation, training, and change support.

- Post-Upgrade Auditing & Optimization – Tune performance and sustain gains after hypercare.

This cadence unites client-side program leadership with vendor-side execution, so decisions stay grounded in business outcomes and operational realities.

Two Common Journeys

For fast-growing operations

When growth exposes the limits of legacy processes, a paired client/vendor model keeps scope realistic and momentum high. Client-side leadership ensures the roadmap reflects commercial priorities; vendor-side expertise ensures throughput, labor, and inventory flows are designed and validated for how work truly happens. Expect shorter cycle times, fewer touches, tighter service levels, and a system that scales without drama.

For multi-site networks

When the challenge is consistency across buildings, combining client-side standards and governance with vendor-side implementation rigor pays off. Clear roles, robust testing, practical SOPs, and role-based training help standards turn into daily habits. Expect steadier output, cleaner data, simpler onboarding, and a foundation for continuous improvement across the network.

In both paths, specifics vary by business. The advantage stays constant: coordinated client-side and vendor-side support aligned to one plan and one outcome-yours.

What Makes the Two-Firm Model Work

- Two perspectives, one plan

Client-side advocacy keeps business goals front-and-center; vendor-side depth ensures integration, performance, and stabilization land cleanly. - Outcome-first execution

Success isn’t merely “system live.” It’s measurable improvements in throughput, quality, and service that persist after hypercare. - Operational practicality

Documentation, training, and coaching reflect real workflows so supervisors and associates can succeed on day one. - De-risked, without slowing down

A proven, gated framework reduces scope, data, and cutover risk while maintaining pace, so you see tighter timelines with minimal disruption to daily operations. - Momentum beyond go-live

Post-upgrade audits and optimization cycles turn early wins into sustained performance. - About the cost

Working with two firms doesn’t mean paying twice. The partnership model is built around clear ownership, complementary expertise, and unified delivery. That means no duplicate overhead, no redundant project management, and no finger-pointing over scope. You get a single, integrated team that shares accountability. In many cases, the shared model reduces total cost by accelerating timelines, avoiding rework, and minimizing disruption to day-to-day operations.

What You Can Expect

- Less risk, tighter timelines through coordinated planning, realistic scopes, and proven cutover playbooks.

- Seamless migrations rooted in clean data practices and integrated testing.

- Adoption that sticks thanks to usable SOPs, work instructions, and role-based training.

- Continuous improvement with post-go-live tuning to lock in gains and surface new opportunities.

Pairing client-side leadership with vendor-side execution is how you buy outcomes, instead of just software.

Ready to talk?

If you’re planning a new WMS implementation or an upgrade and want a streamlined, outcome-driven path, let’s talk.

About Alpine Supply Chain Solutions

Alpine Supply Chain Solutions is a boutique consulting firm specializing in warehouse optimization, supply chain strategy, and distribution network efficiency. Through data-driven analysis and hands-on expertise, Alpine helps companies enhance operational performance, reduce costs, and scale for growth. For more information visit alpinesupplychainsolutions.com.

About Longbow Advantage

Longbow Advantage helps leading supply chain organizations implement, integrate, and optimize warehouse management (WMS), labor management (LMS), and automation systems with precision and efficiency. With more than 65% of its delivery team bringing hands-on supply chain experience, Longbow combines deep industry expertise with a proven methodology to deliver faster project mobilization, seamless migrations, and measurable operational results. For more information about Longbow Advantage, visit longbowadvantage.com.

7 Tips to Improve Your WMS Implementation

A Warehouse Management System implementation is one of the most significant initiatives a distribution operation can undertake. When executed well, it improves inventory accuracy, labor productivity, and service levels. When it falls short, it can disrupt operations, frustrate users, and delay ROI.

The difference between success and struggle rarely comes down to the software alone. It comes down to preparation, execution, and what happens after go-live. Based on industry best practices and real-world implementation experience, here are seven tips to help ensure your WMS implementation delivers lasting value.

1. Start with Clear Goals and Operational Alignment

Before any configuration begins, define what success looks like for your operation. Vague objectives like “improve efficiency” leave too much open to interpretation. Instead, align stakeholders around specific, measurable outcomes such as increasing inventory accuracy, reducing order cycle time, or improving labor utilization.

Clear goals guide system design decisions, prioritize requirements, and provide a benchmark for measuring success after go-live. This early alignment phase is often where strong implementations are won or lost.

2. Understand and Standardize Your Current Processes

A WMS will not fix broken processes. It will automate whatever workflows you give it.

Before implementing new technology, take time to understand how work is actually performed on the warehouse floor today. Document receiving, putaway, picking, replenishment, and shipping processes as they exist, not as they are assumed to exist. Identify inconsistencies across shifts, teams, or facilities and standardize wherever possible.

This discovery work creates a strong foundation for solution design and helps ensure the system supports efficient, repeatable workflows rather than reinforcing bad habits.

3. Build a Cross-Functional Project Team

WMS implementations are not IT-only projects. They require input and ownership from across the organization.

A strong project team typically includes operations leaders, warehouse supervisors, inventory control, IT, and finance. Each role brings a different perspective that helps prevent blind spots. Clear ownership and decision-making authority also keep the project moving when trade-offs are required.

When operational leaders are actively involved, the system is more likely to reflect real-world needs and gain user acceptance.

4. Prepare and Validate Your Data Early

Clean data is essential to a smooth WMS implementation. Inaccurate or incomplete item masters, location data, units of measure, or inventory balances can cause issues from day one.

Data preparation should begin early and include cleansing, standardization, and validation. This is especially critical during data migration, when legacy issues have a tendency to surface under tight timelines.

Investing time upfront reduces go-live risk, minimizes disruptions, and builds confidence in the system among users.

5. Prioritize Training and Change Management

A WMS is a people project as much as a technology project. When users don’t understand why the system Even the best-configured WMS will fail if users are not prepared to adopt it.

Training should be role-based and focused on real tasks employees perform every day. Warehouse associates, supervisors, and managers all interact with the system differently and need training that reflects those responsibilities.

Equally important is change management. Communicate why the new system is being implemented, how it improves daily work, and what success looks like after go-live. When people understand the purpose behind the change, adoption happens faster and with less resistance.

6. Test the System in Real-World Scenarios Before Go-Live

Thorough testing is critical to avoiding surprises during go-live. This includes unit testing, integration testing with upstream and downstream systems, and user acceptance testing with real warehouse scenarios.

Testing should reflect peak volumes, exception handling, and edge cases, not just ideal conditions. Giving users hands-on exposure during testing also helps identify gaps and builds familiarity before the system goes live.

The goal is to resolve issues early, when they are easier and less disruptive to fix.

7. Plan for Post-Go-Live Support and Continuous Optimization

Go-live is not the finish line. It is the beginning of operational improvement.

After launch, closely monitor performance metrics and user feedback. Expect adjustments as real-world usage highlights opportunities for refinement. Many organizations see their greatest gains when they continue optimizing configurations, workflows, and reporting after stabilization.

A structured post-go-live support period helps ensure the system delivers sustained value and adapts as business needs evolve.

Final Thoughts

Successful WMS implementations are built on disciplined planning, operational understanding, and continuous improvement. By aligning goals early, standardizing processes, preparing data, supporting users, and planning beyond go-live, organizations can reduce risk and accelerate ROI.

A WMS is more than a technology upgrade. It is an operational transformation. Approaching it with the right structure and mindset makes all the difference.

Looking for support as you prepare to implement a WMS?

If you’re preparing for a WMS implementation and want to reduce risk, avoid common pitfalls, and set your operation up for long-term success, Longbow Advantage can help. Our team brings deep, hands-on experience across leading WMS platforms and complex warehouse environments, providing independent guidance from planning and process design through go-live and optimization.

Whether you need strategic direction, implementation support, or an experienced partner to complement your internal team, we help ensure your WMS delivers real operational results. Contact us to start the conversation.

How to Maintain Employee Morale When Implementing Labor Standards in Warehouses

Engineered labor standards are one of the most powerful tools warehouse leaders have to improve productivity, create fairness, and uncover operational waste. They are also one of the fastest ways to damage trust if rolled out poorly.

Many distribution centers learn this the hard way. What starts as a well-intentioned efficiency initiative quickly turns into pushback, disengagement, and a perception that management cares more about numbers than people. The result is often worse performance than before.

The challenge is not whether labor standards matter. They do. The real challenge is how to implement them in a way that strengthens operations without eroding morale. That requires a people-first approach grounded in transparency, realism, and collaboration.

Below are practical strategies warehouse leaders can use to strike that balance.

Acknowledge the Challenge Up Front

Labor standards exist for good reasons. They help leaders understand true capacity, balance workloads, plan labor more accurately, and identify process inefficiencies. When done well, they can actually make work more fair by setting consistent expectations instead of relying on gut feel or favoritism.

Employees, however, often see something very different.

From the floor, labor standards can feel like a threat. Associates worry about unrealistic expectations, loss of autonomy, or being punished for factors outside their control. Many have experienced past initiatives where standards were introduced quietly, enforced aggressively, and never adjusted when reality changed. That history creates skepticism and distrust.

Ignoring those concerns does not make them go away. Acknowledging them openly is the first step toward earning buy-in. Leaders who recognize the emotional side of labor standards signal that this is not just a math exercise. It is a change that affects real people doing real work.

Build Transparency into the Process

One of the fastest ways to lose trust is to treat labor standards like a black box.

Employees need to understand the why. Why are standards being introduced now? What problems are they meant to solve? How will success be measured? Most resistance comes from uncertainty, not laziness.

Transparency also means explaining how standards are developed. Associates should know whether times are based on engineered studies, historical data, or assumptions. They should understand what is included and what is not. If allowances are built in for breaks, fatigue, and variability, say so clearly.

When people understand how expectations are set, standards feel less arbitrary. They become something to engage with rather than something being done to them.

Involve Employees Early and Often

Labor standards should never be created in isolation from the people who do the work.

One effective approach is to use pilot programs before a full rollout. Select a small area, a limited set of tasks, or a volunteer group to test standards in real conditions. This creates space to identify gaps, refine assumptions, and learn what works before scaling.

Employee committees can also play a powerful role. Involving experienced associates in validating standards builds credibility and surfaces practical insights that engineers and managers may miss. It also sends a clear message that employee input matters.

When associates help shape the standards, they are far more likely to trust them and defend them.

Keep Standards Fair and Realistic

Nothing undermines morale faster than goals that feel unattainable.

Fair standards must account for the realities of warehouse work. That includes natural variability in order profiles, travel distances, congestion, equipment availability, and human fatigue. Breaks and allowances are not optional extras. They are essential components of any credible standard.

It is also important to separate standards from punishment. When expectations are framed as minimums tied directly to discipline, fear quickly replaces engagement. Standards should represent reasonable performance for a trained associate working under normal conditions, not peak performance on a perfect day.

Fairness builds trust. Unrealistic targets destroy it.

Implement Gradually and Use Standards as Coaching Tools

Even well-designed standards can fail if implementation is rushed or heavy-handed.

Supervisors play a critical role here. They need training not just on what the standards are, but how to use them constructively. Standards should support coaching conversations, process improvement, and workload balancing, not constant policing.

Gradual implementation gives everyone time to adapt. Start with visibility and education before enforcement. Use early data to identify process issues rather than individual shortcomings. When performance gaps appear, ask why before assigning blame.

It also helps to clearly communicate employee benefits. Labor standards can enable fairer workload distribution, reduce burnout in high-volume areas, and create objective criteria for recognition and advancement. When associates see how standards improve their day-to-day experience, resistance decreases.

Create Quick Wins That Build Trust

Pairing a labor standards rollout with visible improvements can accelerate buy-in.

Quick wins might include fixing long-standing process irritants, improving equipment availability, adjusting slotting, or addressing safety concerns that employees have raised repeatedly. These changes demonstrate that management is listening and acting, not just measuring.

Celebrating progress matters too. Recognize teams that help refine standards, identify waste, or improve processes. Highlight examples where employee feedback led to real changes. Public acknowledgment reinforces collaboration and shared ownership.

Trust grows when people see their input reflected in outcomes.

Efficiency and Morale Are Not Opposites

The idea that labor standards must come at the expense of morale is a false tradeoff. The real issue is not the standards themselves, but how they are introduced and used.

Warehouses that succeed take a human-centered approach. They communicate clearly, involve employees, design fair expectations, and treat standards as tools for improvement rather than control. Over time, this builds a culture where performance data is seen as helpful, not threatening.

At Longbow Advantage, we see this play out every day. The most successful operations are the ones that treat labor standards as part of a broader partnership between leadership and the workforce.

Efficiency and trust can coexist. But only if leaders choose to build both intentionally.

Looking for support as you roll out labor standards?

Longbow Advantage works alongside warehouse and distribution leaders to share practical insights, lessons learned, and data-driven perspectives that support fair, effective labor standards implementations. If you’d like to talk through your situation or explore available options, we’re happy to start a conversation.

Continuous Improvement Doesn’t Have to Mean Continuous Disruption

For many warehouse leaders, the phrase “continuous improvement” triggers an immediate reaction. More projects. More meetings. More disruption to an operation that is already stretched thin.

That hesitation is understandable. Warehouses run on tight schedules, fixed labor, and daily execution. The idea of reopening processes after a WMS implementation can feel risky, especially if the system is stable and orders are moving.

But continuous improvement does not have to mean constant upheaval. When done right, it is incremental, targeted, and designed to work around daily operations, not against them.

At Longbow Advantage, we see continuous improvement as a way to quietly unlock value that already exists inside your WMS and your operation, without putting go-live stability at risk.

Why Stability Is Not the Same as Optimization

After a WMS implementation, most organizations focus on stabilization first. That is the right call. Teams need time to learn the system, adjust to new workflows, and build confidence.

The problem is what happens next.

Once the system is stable, many organizations stop looking at it critically. Temporary workarounds become permanent. Manual checks stay in place even when the system can handle them. Processes grow more complex over time as exceptions stack on top of exceptions.

The operation works, but it works harder than it needs to.

Continuous improvement is about recognizing that stability is only the starting point. Optimization comes from revisiting processes with real operational experience in hand and asking one simple question: is this still the best way to do this?

The Fear of Disruption and Why It Persists

One of the biggest barriers to continuous improvement is the assumption that it requires large, disruptive initiatives. Full redesigns. Major retraining. Long timelines with uncertain outcomes.

In reality, most meaningful gains come from much smaller changes.

In many post-implementation assessments, we find opportunities that do not require new modules, new systems, or large-scale change management. Instead, they involve refining workflows, simplifying decision points, and better aligning system configuration with how the warehouse actually operates.

These are changes that can be planned, tested, and rolled out incrementally, often without frontline users even realizing a project is underway.

What Incremental Improvement Really Looks Like

Effective continuous improvement starts with focus.

Rather than trying to fix everything at once, Longbow approaches improvement by isolating individual functional areas or processes and evaluating them on their own merits. Receiving. Allocation. Picking. Putaway. Reporting.

Each area is reviewed with subject matter experts who live in the process every day. Their input matters because they know where time is lost, where workarounds exist, and where frustration shows up repeatedly.

From there, processes are examined step by step with a simple lens:

- Is this step required?

- Is it solving a real problem?

- Is it duplicated elsewhere in the workflow?

- Could the WMS handle this automatically?

This approach keeps the scope tight and the risk low.

A Simple Example with a Big Impact

In one engagement, Longbow reviewed an outbound allocation process that had grown to more than 40 steps over time. Each step made sense in isolation. Together, they created unnecessary complexity.

During review, the team identified decisions that were being made multiple times, checks that existed only because of outdated assumptions, and manual steps that the WMS could already manage automatically.

By removing redundancy and aligning the process more closely with standard system behavior, the workflow was reduced to a fraction of its original size. The result was faster execution, clearer accountability, and fewer errors.

No system upgrade was required. No operational shutdown was needed. The improvement came from simplifying what already existed.

Continuous Improvement Without Operational Whiplash

Another common concern is timing. Warehouse leaders worry that improvement initiatives will pull key people away from daily execution.

That is why the most effective continuous improvement efforts are structured around the operation, not layered on top of it.

At Longbow, assessments are designed to respect operational realities. Interviews are targeted. Onsite walkthroughs are purposeful. Recommendations are prioritized so teams can choose when and how to act on them.

Not every opportunity needs to be addressed at once. Some changes deliver immediate ROI. Others can wait until the business is ready.

This flexibility allows organizations to improve continuously without overwhelming their teams.

Turning Small Changes into Measurable ROI

Continuous improvement is often misunderstood as a theoretical exercise. In practice, it is one of the most reliable ways to accelerate return on investment after go-live.

When processes are simplified, throughput improves. When manual steps are eliminated, labor is used more effectively. When reporting aligns with how the operation actually runs, leaders make better decisions faster.

These gains add up.

In post-implementation assessments, it is common to uncover dozens of improvement opportunities across functional areas. By evaluating each opportunity based on effort and impact, organizations can focus on the changes that deliver value quickly, without committing to large-scale projects.

Why Experience Matters

Not all continuous improvement efforts are equal.

What makes the difference is practical experience. Knowing how a WMS is designed to function. Understanding how warehouses operate under real-world constraints. Recognizing when a process issue is truly operational versus when it is driven by configuration.

Longbow’s approach is rooted in decades of hands-on implementation and operational experience. Improvement recommendations are not generic best practices. They are grounded in what works, what scales, and what actually sticks.

The Takeaway

Continuous improvement does not have to be disruptive to be effective.

When approached incrementally, with a clear understanding of both the system and the operation, it becomes a way to quietly improve performance while protecting stability.

If your WMS has been live long enough for habits to form, but not so long that inefficiencies feel permanent, now is the right time to take a closer look.

Need some guidance? We’re ready to help.

The Future of Warehouse Efficiency: Leveraging AI for WMS implementations

Introduction

Artificial intelligence (AI) is not just a passing trend. It is reshaping how we think about process optimization, data interpretation, and long-term scalability across industries. For warehouse and supply chain operations, AI is becoming a key differentiator between companies that simply keep up and those that set new standards for efficiency and innovation.

The real opportunity lies in how AI can enhance the systems and methodologies that drive daily warehouse operations. Tools such as Warehouse Management Systems (WMS), supply chain execution software, and integration frameworks can all benefit from AI. When applied correctly, AI can strengthen delivery predictability, accelerate time-to-value, and improve scalability across implementations and ongoing operations.

Rethinking AI in the Warehouse

When most people think about AI in warehouse environments, they picture robotics or automation such as machines picking, sorting, or transporting goods. While those technologies are important, they only represent a small part of the potential.

Directionally speaking, the next phase of progress will come from embedding AI directly into methodologies and governance toolkits. When AI becomes part of the delivery foundation and understands templates, processes, and standards, it transitions from being a helper to being an integrated part of operational excellence.

Instead of simply generating ideas, AI can learn to apply and scale proven practices automatically, creating more predictable implementations and measurable performance outcomes. The goal is not for AI to replace expertise but to amplify it.

Building the Right Foundation: Context is Everything

One of the biggest lessons from early AI experimentation is that context matters.

AI on its own is not intelligent in the way humans are. It needs structure, input, and direction. By grounding it in reference materials such as configuration standards, integration rules, or process documentation, teams can train AI to think and act within an established framework. Once those inputs exist, the outputs become far more meaningful.

In one early test, I used AI to analyze and update a legacy code sample based on established guidelines. The AI quickly identified multiple areas for correction and generated an improved version that was roughly 85 percent accurate before refinement. It was not perfect, but it reduced hours of manual effort and served as a strong foundation for review.

For teams managing aging codebases or migrating to new system architectures, that type of head start can dramatically shorten delivery cycles and improve time-to-value.

AI as a Co-Pilot, Not an Autopilot

Implementing AI does not mean handing over control to a machine. The most effective approach treats AI as a co-pilot: a system that analyzes large volumes of information, identifies inefficiencies, and suggests optimizations while human experts make the final decisions.

In the context of warehouse environments, that can mean:

- Accelerating code modernization: AI can help bring legacy configurations or integrations up to current standards, reducing technical debt.

- Improving compliance and quality: AI can review thousands of lines of code or configuration to ensure alignment with project rules or governance models.

- Streamlining documentation: Instead of manually drafting or updating documentation, AI can generate initial versions for teams to validate and refine.

- Enhancing performance optimization: By analyzing operational data, AI can identify bottlenecks and recommend tuning or parameter changes.

In each case, AI does not replace human intelligence. It multiplies efficiency and precision, resulting in faster delivery, fewer errors, and stronger alignment with business objectives.

Why This Matters for Supply Chain Leaders

For organizations managing complex warehouse networks, the gap between functional and optimized operations has a direct impact on profitability. Integrating AI into warehouse methodologies should aim to:

- Shorten time-to-value and accelerate deployment cycles

- Reduce manual rework and repetitive tasks

- Improve governance and compliance consistency

- Increase system scalability and reliability across facilities

Beyond measurable efficiency, AI brings greater predictability to delivery timelines and outcomes. This ensures that projects stay aligned with both operational goals and investment expectations.

As supply chain ecosystems evolve, AI will increasingly become part of the operational fabric, reinforcing both strategic agility and long-term resilience.

At Longbow, we’ve spent years refining our understanding of how to combine deep operational expertise with data-driven insight. AI is simply part of the next step in that journey. By bringing intelligence into the heart of how we configure, test, and maintain warehouse systems, we’re defining innovation.

Bringing AI Into Real-World Warehouse Intelligence

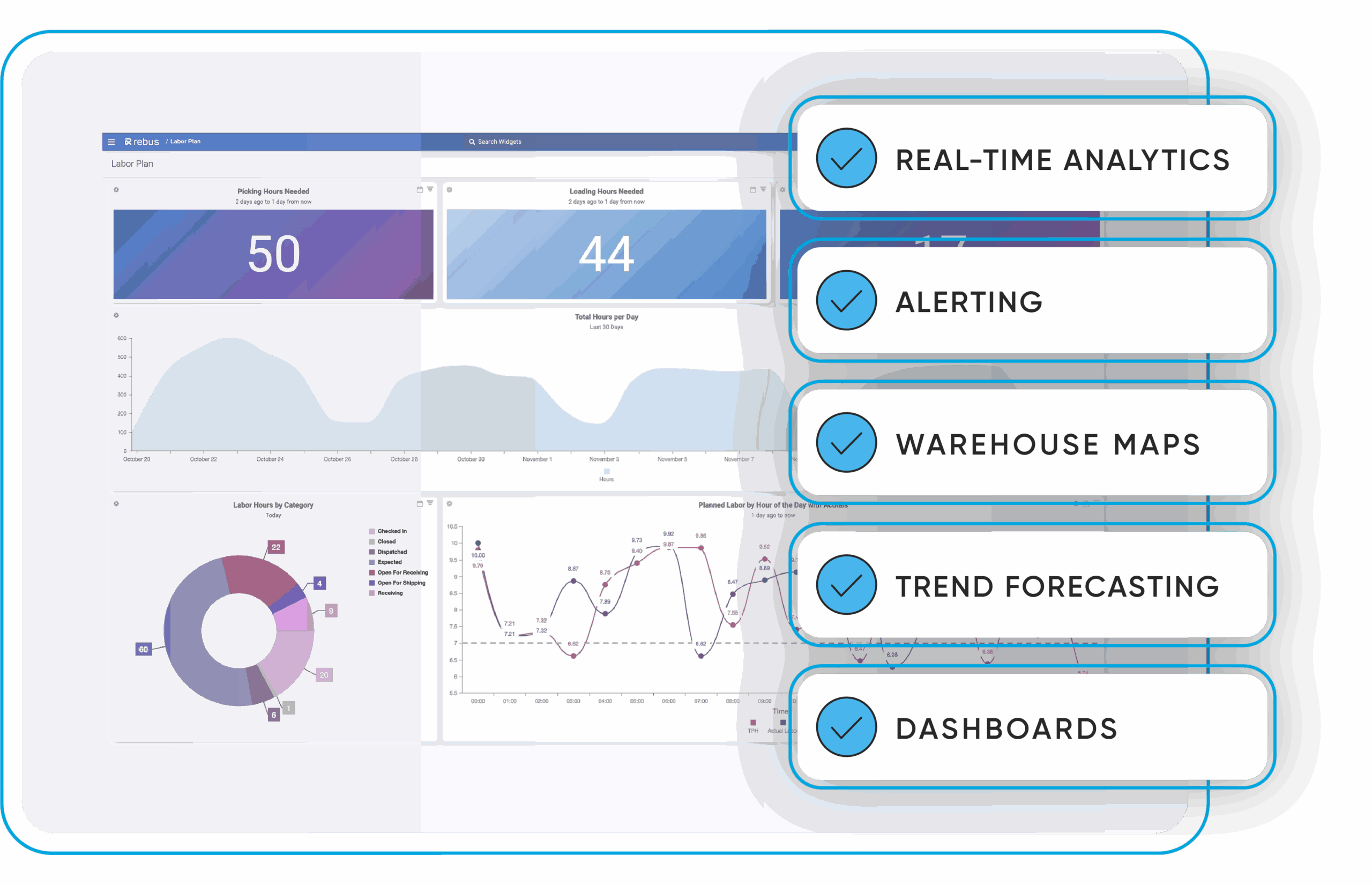

As part of our commitment to operational excellence, Longbow is applying these same AI principles within our own technology ecosystem, including Rebus—our real-time SaaS platform that unifies labor, automation, and inventory data into actionable intelligence. Rebus now incorporates AI to expand its analytics capabilities, helping warehouse teams uncover deeper patterns, forecast trends with greater accuracy, and accelerate operational decision-making.

Earlier this year, we introduced AI Trend Forecasting to give organizations a forward-looking view of labor and performance indicators. Building on that momentum, we recently launched AI-driven dashboards that automatically surface key insights and flag emerging issues, dramatically reducing the manual effort traditionally required to interpret complex operational data.

These advancements reflect the same principles guiding our broader AI strategy: combining deep operational expertise with structured methodologies to deliver practical, measurable value. By embedding AI into both our delivery frameworks and our technology ecosystem, we’re helping supply chain leaders achieve greater predictability, scalability, and speed across their warehouse operations.

The Road Ahead

We’ve moved beyond experimentation. Early results already show that AI can streamline configuration, testing, and deployment workflows while improving governance and reducing manual effort. The next evolution lies in training AI systems to operate within refined methodologies, creating a future where these tools handle the heavy lifting so people can focus on innovation, problem-solving, and strategic execution.

AI is not here to replace the warehouse workforce. It is here to make their work smarter, faster, and more rewarding. The more we embed AI into structured processes and governance frameworks, the more it will drive measurable improvements in performance, scalability, and time-to-value.

At Longbow Advantage, that’s what we’re building toward: a smarter, more connected, and more efficient future for warehouse operations.

Interested in learning how AI could accelerate time-to-value and drive efficiencies in your warehouse operations?

Contact us to start the conversation.

Longbow Advantage and Softeon Announce Strategic Partnership to Deliver Seamless Warehouse Implementations

MONTREAL, QUEBEC, CANADA | November 12, 2025 — Longbow Advantage, a trusted leader in supply chain technology consulting and data visibility solutions, announced a strategic partnership with Softeon, the only tier-1 warehouse management system (WMS) provider exclusively focused on optimizing warehouse and fulfillment performance to increase operational efficiency.

This partnership brings together Longbow’s 25+ years of implementation expertise with Softeon’s best-in-class WMS technology, to deliver more seamless, efficient, and insight-driven supply chain transformations for customers worldwide.

As Longbow continues to expand its implementation and integration capabilities, this partnership adds Softeon’s modern, flexible WMS platform to its portfolio. This enables Longbow consultants to provide clients with a proven solution designed to orchestrate complex fulfillment operations with speed and precision.

Longbow Advantage brings deep supply chain expertise and a consultative, hands-on approach that goes far beyond software implementation. Acting as a true strategic partner, Longbow’s team of subject matter experts advises, designs, and operationalizes solutions that drive measurable business outcomes. Leveraging best-in-class frameworks and proven toolkits, Longbow helps organizations accelerate time-to-value, reduce implementation risk, and ensure that technology investments translate into real operational performance.

“We’re proud to partner with Softeon to deliver practical WMS transformation built on experience, discipline, and innovation,” said Ryan Uhlenkamp, CEO of Longbow Advantage. “Softeon’s modern, flexible WMS pairs perfectly with our operational expertise and structured delivery frameworks, giving customers faster time-to-value, greater predictability, and confidence that their technology will perform in the real world.”

From methodology to execution, the partnership combines Longbow’s proven project frameworks and experienced consulting team with Softeon’s configurable and scalable WMS. Together, the companies will deliver implementations that reduce complexity, improve visibility, and drive continuous performance improvement.

“At Softeon, we’ve always believed that the best technology deserves the best implementation experience,” says Jim Hoefflin, CEO, Softeon. “Partnering with Longbow, an organization that shares our deep operational knowledge and customer-first philosophy, ensures that our customers can realize faster time-to-value and more predictable outcomes from their WMS investment.”

About Longbow Advantage

Longbow Advantage helps leading supply chain organizations implement, integrate, and optimize warehouse management (WMS), labor management (LMS), and automation systems with precision and efficiency. With a focus on data-driven solutions, Longbow helps organizations optimize warehouse and distribution center operations.

In addition to its consulting expertise, Longbow continues to innovate through solutions like Rebus, which unifies data across disparate warehouse and supply chain systems to deliver real-time operational insights and smarter decision-making.

For more information about Longbow Advantage, visit longbowadvantage.com.

About Softeon

Softeon is a WMS provider focused exclusively on optimizing warehouse and fulfillment operations. For over two decades, Softeon has been helping our customers succeed in optimizing their fulfilment operations. Investing in R&D enables us to develop software to solve the most complex warehouse challenges. Softeon is laser-focused on customer results, with a 100% track record of deployment success. We believe warehouse leaders shouldn’t have to settle for a one-size-fits-all approach to technology. For more information, please visit www.softeon.com.