A Tale of Two WMS Implementations: Why Two Consulting Firms Can Be Better Than One

Feb 11th, 2026

Big warehouse programs don’t stumble on vision-they stumble when complexity across client-side leadership and vendor-side execution isn’t coordinated. Blue Yonder WMS affects people, process, data, and tech. Getting it right means combining a partner who champions your interests on the client side with a partner who brings deep vendor-side operational and integration expertise. That’s the strength of Alpine Supply Chain Solutions and Longbow Advantage working as one team: clear ownership, complementary skills, and outcomes that hold after go-live.

Together, these teams bring more than 400 successful WMS projects led by seasoned practitioners. As Longbow CEO Ryan Uhlenkamp puts it, warehouse leaders “don’t just buy software, they buy outcomes.” Alpine’s Michael Wohlwend echoes that alignment: the partnership assembles one of the industry’s deepest implementation benches, ready to deliver value quickly and consistently.

All organizations can benefit from this because you’re getting both lenses that matter: a client-side advocate ensuring the program serves your business goals, and a vendor-side specialist ensuring the system is built, integrated, and stabilized the right way.

A Proven End-to-End WMS Implementation Framework

Our joint approach follows a practical, multi-step path that protects day-to-day operations while your system takes shape:

- Discovery – Align stakeholders, assess current workflows and data, and clarify business objectives.

- Solution Design – Configure Blue Yonder WMS to real-world processes with a pragmatic “to-be” state.

- Build & Integration – Stand up environments, ready data, and connect adjacent systems.

- Implementation & Data Migration – Execute the plan with disciplined cutover management.

- Testing & Go-Live – Validate end-to-end flows, stabilize performance, and prepare the floor for day one.

- SOPs, Work Instructions & OCM – Equip teams with usable documentation, training, and change support.

- Post-Upgrade Auditing & Optimization – Tune performance and sustain gains after hypercare.

This cadence unites client-side program leadership with vendor-side execution, so decisions stay grounded in business outcomes and operational realities.

Two Common Journeys

For fast-growing operations

When growth exposes the limits of legacy processes, a paired client/vendor model keeps scope realistic and momentum high. Client-side leadership ensures the roadmap reflects commercial priorities; vendor-side expertise ensures throughput, labor, and inventory flows are designed and validated for how work truly happens. Expect shorter cycle times, fewer touches, tighter service levels, and a system that scales without drama.

For multi-site networks

When the challenge is consistency across buildings, combining client-side standards and governance with vendor-side implementation rigor pays off. Clear roles, robust testing, practical SOPs, and role-based training help standards turn into daily habits. Expect steadier output, cleaner data, simpler onboarding, and a foundation for continuous improvement across the network.

In both paths, specifics vary by business. The advantage stays constant: coordinated client-side and vendor-side support aligned to one plan and one outcome-yours.

What Makes the Two-Firm Model Work

- Two perspectives, one plan

Client-side advocacy keeps business goals front-and-center; vendor-side depth ensures integration, performance, and stabilization land cleanly. - Outcome-first execution

Success isn’t merely “system live.” It’s measurable improvements in throughput, quality, and service that persist after hypercare. - Operational practicality

Documentation, training, and coaching reflect real workflows so supervisors and associates can succeed on day one. - De-risked, without slowing down

A proven, gated framework reduces scope, data, and cutover risk while maintaining pace, so you see tighter timelines with minimal disruption to daily operations. - Momentum beyond go-live

Post-upgrade audits and optimization cycles turn early wins into sustained performance. - About the cost

Working with two firms doesn’t mean paying twice. The partnership model is built around clear ownership, complementary expertise, and unified delivery. That means no duplicate overhead, no redundant project management, and no finger-pointing over scope. You get a single, integrated team that shares accountability. In many cases, the shared model reduces total cost by accelerating timelines, avoiding rework, and minimizing disruption to day-to-day operations.

What You Can Expect

- Less risk, tighter timelines through coordinated planning, realistic scopes, and proven cutover playbooks.

- Seamless migrations rooted in clean data practices and integrated testing.

- Adoption that sticks thanks to usable SOPs, work instructions, and role-based training.

- Continuous improvement with post-go-live tuning to lock in gains and surface new opportunities.

Pairing client-side leadership with vendor-side execution is how you buy outcomes, instead of just software.

Ready to talk?

If you’re planning a new WMS implementation or an upgrade and want a streamlined, outcome-driven path, let’s talk.

About Alpine Supply Chain Solutions

Alpine Supply Chain Solutions is a boutique consulting firm specializing in warehouse optimization, supply chain strategy, and distribution network efficiency. Through data-driven analysis and hands-on expertise, Alpine helps companies enhance operational performance, reduce costs, and scale for growth. For more information visit alpinesupplychainsolutions.com.

About Longbow Advantage

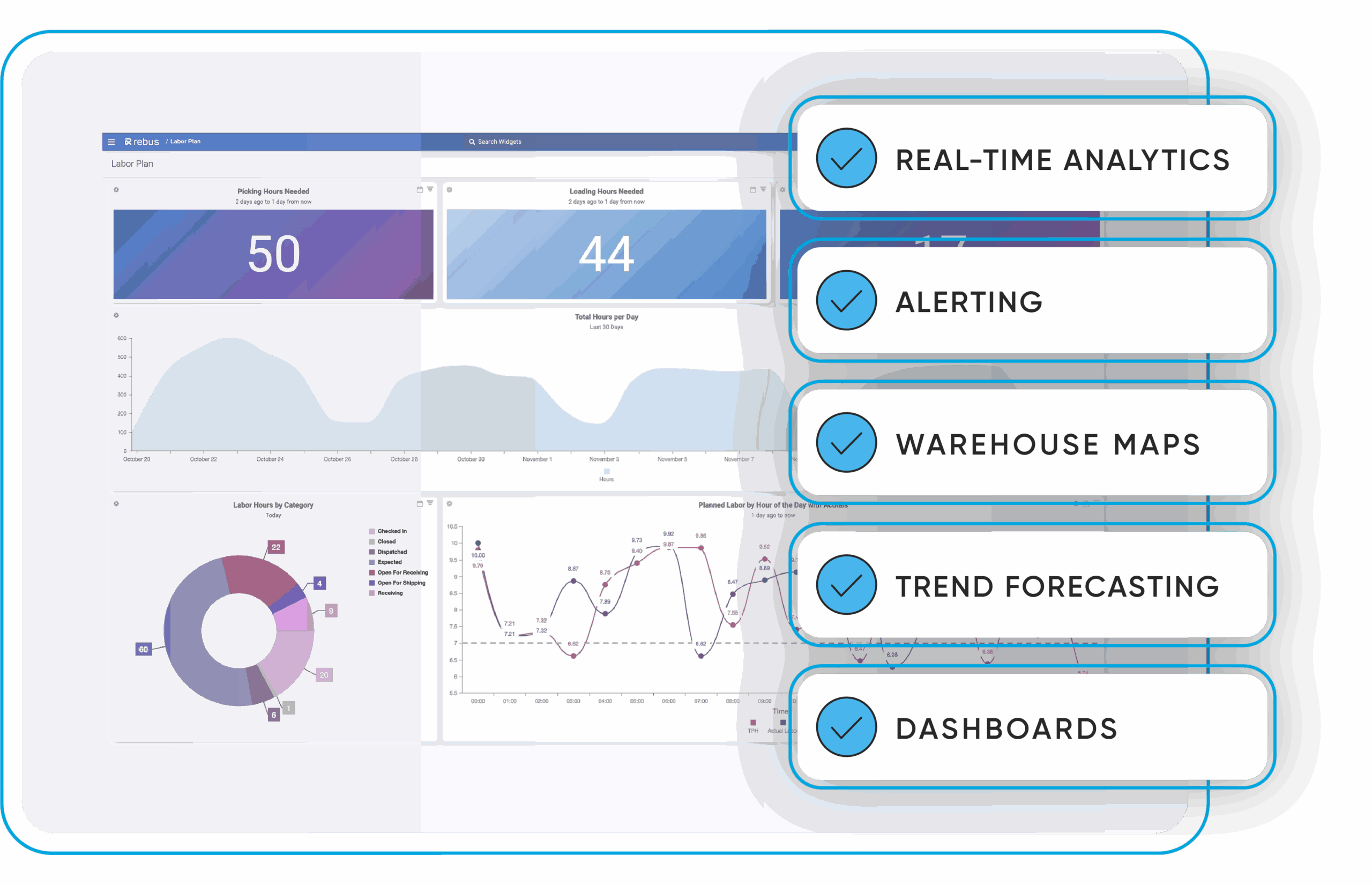

Longbow Advantage helps leading supply chain organizations implement, integrate, and optimize warehouse management (WMS), labor management (LMS), and automation systems with precision and efficiency. With more than 65% of its delivery team bringing hands-on supply chain experience, Longbow combines deep industry expertise with a proven methodology to deliver faster project mobilization, seamless migrations, and measurable operational results. For more information about Longbow Advantage, visit longbowadvantage.com.