Why Every Warehouse Needs a Study Hall

Sep 22nd, 2025

By Brandon McColl, VP Consulting Services, Longbow Advantage

Author Bio

Brandon McColl is Vice President of Consulting Services at Longbow Advantage, where he’s spent nearly 13 years helping companies implement and optimize warehouse and labor management systems. He thrives on turning complex supply chain challenges into practical strategies that drive measurable results. Connect with Brandon on LinkedIn.

Introduction

Years ago, at Longbow Advantage, we needed a way to help our junior team members through tricky project challenges. Senior team members were spread out across separate projects, each working on our own sets of problems, but we needed a way to share our cumulative knowledge and insights to help the whole team grow.

As a result, we built something that I wish every warehouse had: Study Halls.

They started as an informal way to help newer team members, but they’ve grown into something much bigger. Twice a week, our services team logs into a standing call. There’s no slide deck, no formal agenda—just a dedicated space for knowledge sharing, process problem-solving, and pushing each other toward best practices.

These aren’t theoretical discussions. They’re working sessions where our team of consultants bring live project challenges, sticky customer issues, or messy SOPs. Together, the group brings not only hundreds of years of combined warehouse and WMS expertise, but also a shared passion for tackling complex problems and finding smarter, simpler ways to run operations. That’s a lot of brainpower in one room, and when we apply it to a single process, the results are powerful.

How Study Halls Started

Study Halls began as a support system for junior consultants. If someone was stuck on a project—say, a putaway process wasn’t flowing right or a customer hated the way confirmations were happening—they could come to Study Hall, share their screen, and get help from peers who’d been there before.

Very quickly, the format grew beyond troubleshooting. When we didn’t have live project issues to dissect, we started pulling up warehouse processes (allocation, picking, receiving) and asking: What’s really the best way to run this?

That’s when things got interesting.

The Power of Stripping a Process Down

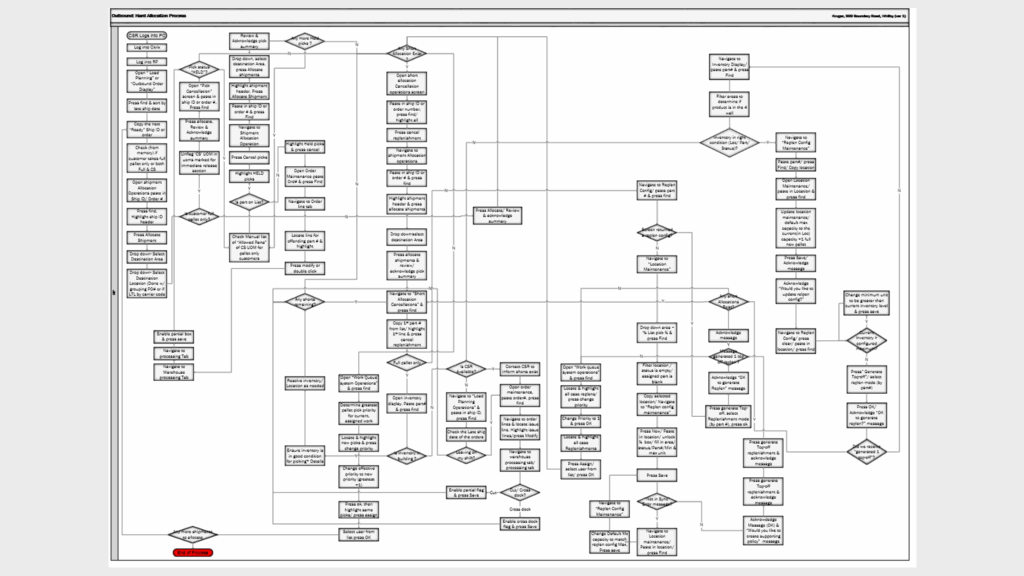

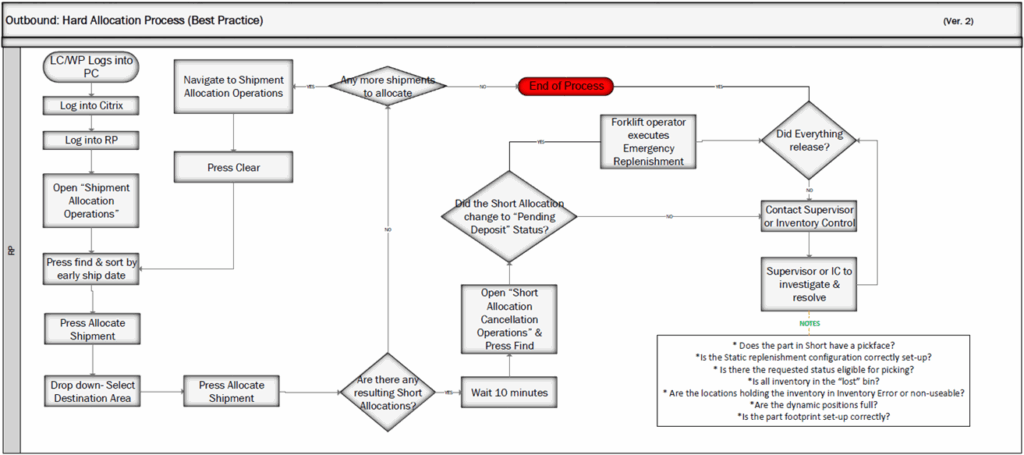

One of the most striking examples came from an allocation workflow. The process was stretched across 42 steps, filled with redundant checks and decision points that caused operators to touch the same issue multiple times. It was messy, confusing, and slow.

We put it through Study Hall. The group walked through it step by step and asked:

- Is this step really necessary?

- Does the system already handle this?

- Could these two steps be combined?

- Does this align to best practice?

By the time we finished, the process was down to just 12 steps. Same outcome, but leaner, faster, and fully aligned to WMS best practice.

That’s the kind of clarity Study Halls deliver. By stripping away assumptions and looking at a process with fresh eyes, you uncover waste that day-to-day operators often miss.

Why Warehouses Should Care

Every warehouse runs on three pillars:

- The system drives the process.

- The process should follow best practice.

- System configuration and reporting should reinforce compliance to that best practice.

When these three get out of alignment, bad things happen. Processes become bloated. Operators invent workarounds. Reports stop reflecting reality. And in the worst cases, automation or labor management systems start to fail because the underlying processes aren’t sound.

Study Halls are one way we make sure those three pillars stay aligned. They create a forum for ruthless process simplification and best-practice reinforcement.

What a Study Hall Looks Like

A typical session follows these four steps:

- Kick-off: Someone raises a process for review. It could be a customer SOP, a project workflow, or even just a problem they’re struggling with.

- Deep dive: The team goes through it line by line. Questions get asked, assumptions get challenged, and redundant steps get flagged.

- Optimization: The group agrees on the essential steps—the minimum needed to achieve the outcome in compliance with best practice.

- Knowledge sharing: The refined process becomes part of our internal knowledge base, so the next consultant (and their customers) benefit too.

Sometimes, it’s as practical as saying, “Why are you asking this twice? The WMS already confirms it automatically.” Other times, it’s more strategic, like deciding that a process should be redesigned altogether because it doesn’t align with system capability.

How Warehouses Can Replicate It

You don’t have to be Longbow Advantage to run your own Study Hall. Any warehouse can take the same approach. Follow these simple steps to implement your very own study hall:

Pick a process. It doesn’t need to be your biggest pain point. Start with something manageable-receiving, allocation, or a picking flow.

Collect documentation. Gather the SOP, process map, or workflow diagram that shows how it’s supposed to run.

Assemble a group. Bring together cross-functional stakeholders-operations, supervisors, IT, even a few associates who actually execute the process.

Review together. Ask the tough questions. Which steps are redundant? Where does the system already enforce compliance? What doesn’t add value?

Streamline and document. Capture the optimized version and make it the new standard.

Even if you do this once a month, the compounding effect adds up. You’ll trim fat from your processes, reinforce best practices, and create a culture of continuous improvement.

When You Need a Done-for-You Solution

Of course, not every warehouse has the bandwidth to run Study Halls consistently. If that’s the case, we’re happy to help.

We’ve formalized our Study Halls into a Best Practice Assessment (or Audit). Here’s how it works:

- You choose a process. Maybe it’s allocation, receiving, or outbound picking.

- You submit documentation. An SOP, process flow, or work instruction.

- We review it. Our team conducts an initial pass, then brings it into Study Hall for collective review.

- We optimize. We identify redundancies, flag gaps, and outline what compliance with best practice looks like.

- We present back. You get a streamlined process map and a clear value proposition for reviewing other areas of your operation.

It’s a way to borrow Longbow’s collective expertise without having to build the forum yourself.

Why This Matters Now

Warehousing has never been more complex. Between labor shortages, rising customer expectations, and the push toward automation, there’s little margin for wasted effort.

If your processes are bloated or misaligned with your WMS, those problems multiply. They slow down operators, they create bad data, and they make automation projects riskier.

Study Halls—and the Best Practice Assessments that come from them—help ensure that your foundation is solid. They give you confidence that your system, your processes, and your reporting are all working toward the same goal.

Final Thought

Warehouses don’t fail because of bad people or lack of hard work. They fail when the system, the process, and the reporting fall out of alignment.

Study Halls are how we prevent that at Longbow. Whether you run them yourself or let us run them for you, the discipline of reviewing and optimizing processes against best practices is one of the fastest ways to unlock efficiency.

If you’re ready to see what a streamlined process looks like in your operation, let’s talk.