Longbow Advantage & Alpine Supply Chain Solutions Partner to Offer Joint Implementation Services for Blue Yonder WMS

MONTREAL, QUEBEC, CANADA | October 27, 2025 — Longbow Advantage, an award-winning WMS operations consultancy partner and Alpine Supply Chain Solutions, an established leader in client-side WMS implementations, have teamed up to provide comprehensive WMS implementation services. Collectively, the two firms have successfully completed more than 400 WMS projects led by two of the industry’s most experienced implementation teams.

“Warehouse leaders don’t just buy software, they buy outcomes. By combining Alpine’s client‑side program leadership with Longbow’s deep operational and integration expertise, we’re helping customers stand up the right WMS for their business with less risk, tighter timelines, and measurable results,” said Longbow Advantage CEO, Ryan Uhlenkamp. “Alpine shares our pragmatic, on‑the‑floor approach. That alignment is why this partnership works and why it will deliver immediate value to our shared customers.”

The joint offering follows a proven, multi-step framework designed to achieve business goals while minimizing disruption to daily operations. We start with discovery to map processes, data flows, and KPIs. Next comes solution design that configures the right WMS for real-world workflows and defines integration across ERP, labor, automation, and inventory.

We then build activities and ready the data for implementation and data migration, testing, and go-live. Go-live is supported with hypercare, clear SOPs and work instructions, and embedded change management.

“With Longbow Advantage’s operations and WMS expertise along with the client-side implementation expertise Alpine brings to every project, I’m thrilled about what this partnership brings to our customers,” added Alpine Managing Principal, Michael Wohlwend. “Longbow and Alpine together represent the industry’s most comprehensive implementation team, led by some of the most experienced professionals available.”

To work with Alpine Supply Chain Solutions and Longbow Advantage on your WMS implementation, contact us here.

About Longbow Advantage

Longbow Advantage helps leading supply chain organizations implement, integrate, and optimize warehouse management (WMS), labor management (LMS), and automation systems with precision and efficiency. With more than 65% of its delivery team bringing hands-on supply chain experience, Longbow combines deep industry expertise with a proven methodology to deliver faster project mobilization, seamless migrations, and measurable operational results. For more information about Longbow Advantage, visit longbowadvantage.com.

About Alpine Supply Chain Solutions

Alpine Supply Chain Solutions is a boutique consulting firm specializing in warehouse optimization, supply chain strategy, and distribution network efficiency. Through data-driven analysis and hands-on expertise, Alpine helps companies enhance operational performance, reduce costs, and scale for growth. For more information visit alpinesupplychainsolutions.com.

5 Warning Signs Your WMS Isn’t Ready for Automation

Introduction

Most automation projects don’t fail because of robots. They fail because the WMS and the processes behind it aren’t ready. If your WMS isn’t the brain—driving real-time decisions, exceptions, and inventory truth—automation becomes an expensive traffic jam. (For example, a client recently spent seven figures on equipment, but because the WMS couldn’t handle cancel messages from the AS/RS, the team reconciled by hand for months.)

Your WMS decides eligibility, allocates work, handles exceptions, and keeps inventory truthful at machine speed. If that brain isn’t ready, the best hardware turns into a very expensive queue.

Why we’re focusing on the WMS

We’ll center these warning signs on the WMS because, in automated operations, it’s the brain that decides what moves when—and why. Robots, shuttles, and conveyors only execute; the WMS allocates work, validates eligibility, reconciles exceptions, and keeps inventory truthful at machine speed. If that brain isn’t ready—if events aren’t real-time, exceptions aren’t modeled, or data isn’t clean—the best hardware becomes an expensive queue.

Facilities, process, and data still matter. Power, floor, and safety set the stage; streamlined workflows reduce waste; high-quality masters inform decisions. But each of those succeeds or fails through the WMS, where rules live and transactions are recorded. That’s why the five warning signs you’re about to read all orbit the same center: a WMS that can truly run automation.

And now, onto the five warning signs your warehouse isn’t ready for automation.

1) The WMS isn’t the system of record (or can’t talk in real-time)

If allocation, eligibility, confirmations, and inventory truth don’t live in the WMS—with bi-directional events in seconds—automation turns into dueling sources of truth. You’ll see tote contents disagree with the WMS, tasks hanging in “in-progress,” and operators forced to click through workarounds in both systems.

The result is rework, inventory drift, and a loss of trust in the numbers that run your SLA. Make the WMS the brain and ensure the automation layer never “owns” inventory—only executes it. When timing matters (short waves, late carrier cutoffs), sub-second event flow is the difference between hitting the truck and missing it.

Quick check: For every automated step, list the WMS events published/consumed (create, confirm, cancel/adjust, error). Note the SLA for each message (<2s typical). Prove with a test that a cancel mid-stream cleanly unwinds inventory and work in both systems.

2) Exceptions aren’t designed end-to-end in the WMS

Happy paths are easy; real operations are made of edge cases. Jams, shorts, label misprints, picker no-reads, and mid-flow order cancels all demand named exception codes, owners, and recovery steps—and they must be modeled where inventory is authoritative: the WMS.

If exceptions “live” only in the controls layer, you’ll fix the physical flow but corrupt the book inventory. That’s when teams start reconciling by hand and throughput falls off a cliff. Build exception paths like products: specify triggers, screens, fields, and the inventory/status updates they drive.

Quick check: For each transaction, document cancel, short, re-route, reprint, and mispick flows: who executes, where (WMS vs. control), what data updates (qty, lot/serial, status), and what the operator sees. In UAT, inject faults on purpose and prove the WMS remains the single point of truth.

3) You’re automating a bad process instead of fixing it

Automation amplifies any wobble in your data. Inconsistent item masters (dims, weights, handling units), messy location types, or casual status usage forces constant human intervention—killing the very ROI you’re buying.

At machine speed, the system needs to trust dimensions for chute eligibility, respect lot/serial rules, and understand each location’s capabilities (putaway, pick, replen) without guesswork. If that foundation is soft, the software stalls, the hardware queues, and operators babysit. Treat item/location masters like production code: versioned, reviewed, and enforced.

Quick check: Validate cycle count accuracy in the target zones (≥99% for high-automation areas). Confirm pack hierarchies, substitution rules, and lot/serial handling are enforced in the WMS (not tribal knowledge). Run a data quality report: % of items with complete dims/weights, % locations with correct type/attributes, and a heatmap of ambiguous statuses.

4) Exception handling is an afterthought

Automation makes good processes faster—and bad processes worse. If replen triggers are late, pick paths cross too often, or wave logic fights carrier SLAs, a shuttle or AMR fleet won’t fix it; it will enshrine it.

Translate your process into WMS rules, priorities, and statuses first. That means clean task interlocks (replen before pick), queue depth limits, and clear service priorities by order type. When these rules live in the WMS, the automation layer executes a coherent plan instead of improvising.

Quick check: Maintain current swimlanes for inbound, replen, picking, packing, shipping—tied to specific WMS tasks and status transitions. In a pilot zone, run A/B waves (current vs. proposed WMS rules) and measure touches/order, queue time, and % on-time to carrier cutoff. Only then should you lock the hardware.

5) Your data quality can’t support machine-speed decisions

Automation touches IT/OT, facilities, safety, and operations—but the integration contract lives with the WMS. Without a single owner, change control, and a test plan that mirrors live throughput and SKU mix, you’ll discover defects at go-live, not in the lab.

Successful teams treat this like a product launch: versioned payloads, performance budgets, rollback paths, and dress rehearsals that use real orders and carrier windows. Tie machine telemetry to WMS tasks so you can diagnose whether slowness is people, software, or equipment.

Quick check: Establish a cross-functional RACI; freeze message schemas with version tags; run unit → integration → performance → “truck-level” dress rehearsal. Define go/no-go criteria (e.g., ≥98% automated confirmations, <2% manual interventions, end-to-end cycle time ≤ target). Have a rollback that returns inventory and tasks to a clean WMS state.

Learn why so many automation implementations fail.

How to get ready (and move fast once you are)

- Make the WMS the brain: confirm event models, timing, and exception flows before hardware is finalized.

- Harden the data: clean item/location masters and enforce status usage in the WMS.

- Design the recovery: document exceptions, owners, and inventory updates.

- Test like you ship: mirror throughput and carrier cutoffs; measure both human and machine utilization.

Conclusion

If you spotted even two of these warning signs, you’re not behind, you’re ahead of trouble. Fixing them now costs far less than fixing them after the steel is bolted and the software is “live.” That’s how you protect ROI and get the throughput you’re buying.

Want an objective readiness check?

If automation is on your roadmap, start by proving your WMS can run it. Longbow Advantage can give you a holistic WMS systems assessment. Our assessment evaluates the health of your WMS—architecture, data, and operations—so you know exactly where you stand before you buy hardware.

Interested in learning more? Reach out to us.

Why Should I Move to a SaaS WMS?

If you’re running a warehouse today, you’ve likely heard the term SaaS WMS more than once. Maybe you’re still using an on-premise warehouse management system that’s served you for years, or maybe you’re exploring new options for your growing business.

Either way, moving to a SaaS WMS is a big decision. It’s not just about switching technology—it’s about setting your warehouse up for better performance, flexibility, and resilience in the years to come.

In this post, we’ll walk through why you should move to a SaaS WMS, how it’s different from older models, the key benefits, and some things to consider before making the move.

What Is a SaaS WMS?

A SaaS WMS is a cloud-based warehouse management system delivered over the internet. Instead of buying servers, installing software onsite, and maintaining everything yourself, you pay a subscription fee to access the software through a web browser.

Think of it like streaming a movie on Netflix instead of buying a DVD. You don’t worry about storage, updates, or repairs—the cloud warehouse software provider handles it all.

Want to take a deep dive into what a WMS is? Learn more here.

The Difference Between SaaS and On-Premise WMS

With an on-premise WMS, your company owns and manages the software and hardware. You pay for licenses upfront, and your IT team handles updates, fixes, and security. This gives you control, but also means higher costs and responsibility for maintenance.

With a SaaS WMS, the provider hosts the software in the cloud. You access it via the internet, and updates happen automatically. You don’t need to worry about server space, complex upgrades, or patching security holes—those are all handled for you.

Why More Warehouses Are Switching to SaaS

Over the last decade, the supply chain world has changed fast. More warehouses are handling e-commerce orders, supply chain disruptions are more common, and customers expect faster, more accurate deliveries. A SaaS WMS can help meet these demands in several key ways.

Lower Upfront Costs

One of the biggest reasons companies switch is cost. An on-premise WMS can require hundreds of thousands of dollars upfront for software licenses, servers, and installation. With a SaaS WMS, you pay a predictable subscription fee, not a big capital investment.

For many businesses, this makes modern WMS capabilities more accessible, especially for smaller warehouses or companies with tight budgets.

Faster Implementation

SaaS WMS solutions can be deployed much faster than traditional systems. Since the software is already running in the cloud, you don’t need to set up servers or wait months for installations.

This speed is crucial if you’re opening a new warehouse, adding seasonal capacity, or replacing a system that’s holding you back.

Easy Scalability

If your business grows—or if demand spikes during the holidays—scaling an on-premise system can be a headache. You may need to buy more hardware, reconfigure your setup, or even upgrade licenses.

With a SaaS WMS, scaling is as simple as adjusting your subscription. Add more users, connect more sites, or handle more transactions without worrying about WMS infrastructure limits.

Automatic Updates and Upgrades

Technology changes fast, and warehouse operations evolve just as quickly. With SaaS WMS software, you automatically get the latest features, security patches, and performance improvements.

This means you won’t fall behind competitors who are using more advanced tools simply because upgrading your system is too costly or complicated.

Better Remote Access and Collaboration

A cloud-based WMS can be accessed from anywhere with an internet connection, whether you’re in the warehouse, working from home, or traveling.

This flexibility makes it easier for managers to oversee operations, for teams to collaborate across multiple sites, and for partners to integrate their systems with yours.

Stronger Security

It might feel counterintuitive, but most SaaS providers can offer stronger security than what many companies manage on their own. Providers invest heavily in data encryption, backup systems, and disaster recovery plans—because protecting your data is critical to their business.

Common Concerns About Moving to SaaS

Even with all these benefits, moving to a SaaS WMS can raise some concerns. Here are a few common ones and how companies address them:

- Internet dependency: SaaS requires a stable internet connection. Many warehouses set up redundant connections to ensure uptime.

- Data control: Some worry about where their data is stored. Reputable providers are transparent about data hosting and offer clear policies for ownership and access.

- Customization: While cloud WMS systems may have limits on deep customization, they often offer robust configuration options and integrations that meet most operational needs.

How to Decide If SaaS Is Right for You

If you’re considering a move, here are some questions to ask:

- Is your current WMS slowing down operations or limiting growth?

- Are IT resources stretched thin maintaining your current system?

- Do you need faster implementation or easier scalability?

- Would predictable monthly costs help with budgeting?

If you answer “yes” to several of these, a SaaS WMS may be a strong fit.

Transition Tips for a Smooth Move

Switching to cloud warehouse software doesn’t have to be disruptive. Here are a few best practices:

- Choose the right provider: Look for a company with proven industry experience and a strong track record.

- Plan your migration: Map out your data transfer, integrations, and training plan before you start.

- Involve your team early: Get warehouse staff involved in testing and feedback so they’re comfortable with the change.

- Use the move as a chance to improve processes: Don’t just replicate your old workflows, optimize them.

The Bottom Line

A SaaS WMS can help warehouses become more agile, cost-efficient, and future-ready. It removes the burden of managing hardware, keeps your technology up to date, and gives you the flexibility to adapt to changing market demands.

The shift might feel like a big step, but for many companies, it’s the move that enables faster growth and smoother operations.

Need expert help with your WMS strategy?

At Longbow Advantage, we’ve helped countless companies evaluate, implement, and optimize WMS solutions—whether SaaS WMS or on-premise. If you’re ready to explore your options, our team can guide you through every step.

Longbow Advantage and Rebus Strengthen Leadership Team to Drive Growth and Market Impact

MONTREAL, QUEBEC, CANADA | March 18, 2025 — Following the recent appointment of Ryan Uhlenkamp as CEO, Longbow Advantage is further strengthening its leadership team to enhance alignment across sales, marketing, and operations. These strategic moves reinforce the company’s commitment to scalable growth and market leadership.

Leigh Chesley has been appointed Chief of Staff to the CEO, a pivotal role that will drive executive alignment, operational execution, and strategic impact. With deep expertise in supply chain technology and a track record of shaping strategic initiatives, Leigh has been instrumental in, developing and leading high-performing teams across the company throughout her tenure and enhancing the customer experience As Chief of Staff , she will serve as a key partner to the CEO, ensuring cross-functional collaboration, accelerating decision-making, and executing on the company’s most critical priorities. Her leadership will be essential in maintaining focus and momentum as Longbow Advantage continues to expand its market presence.

To strengthen revenue growth and improve market positioning, Brian Weiner has been appointed Senior Vice President of Sales & Marketing, unifying these critical functions under a single leader. Since joining last summer, Brian has built a results-driven sales organization, modernized the company’s go-to-market strategy, and driven meaningful pipeline expansion. His ability to align sales execution with market trends and customer needs has already delivered significant impact. In this expanded role, Brian will lead the charge in strengthening market presence and ensuring Longbow is well-positioned for sustained revenue growth in an increasingly competitive landscape.

As Longbow continues to scale, the company is also elevating its investment in brand and demand generation. Jenny Bunn has joined the leadership team, bringing deep expertise in shaping high-growth marketing strategies. With over 12 years of experience in brand marketing and demand generation, Jenny has a proven track record of translating market insights into compelling messaging and strategies, driving growth and accelerating pipeline expansion. Her expertise will be critical in strengthening and amplifying the company’s impact, positioning Longbow for continued market success.

“These changes position us for our next stage of growth by ensuring greater alignment, stronger market presence, and an even deeper focus on delivering value for our customers,” said Ryan Uhlenkamp, CEO of Longbow Advantage. “By strengthening alignment, expanding our market presence, and building on the momentum we’ve created, we are positioning Longbow Advantage for record-breaking growth and customer impact.”

As Longbow Advantage and Rebus continue to evolve, these leadership enhancements reinforce a strategic focus on innovation, execution, and setting new benchmarks for success in the supply chain industry.

About Longbow Advantage and Rebus

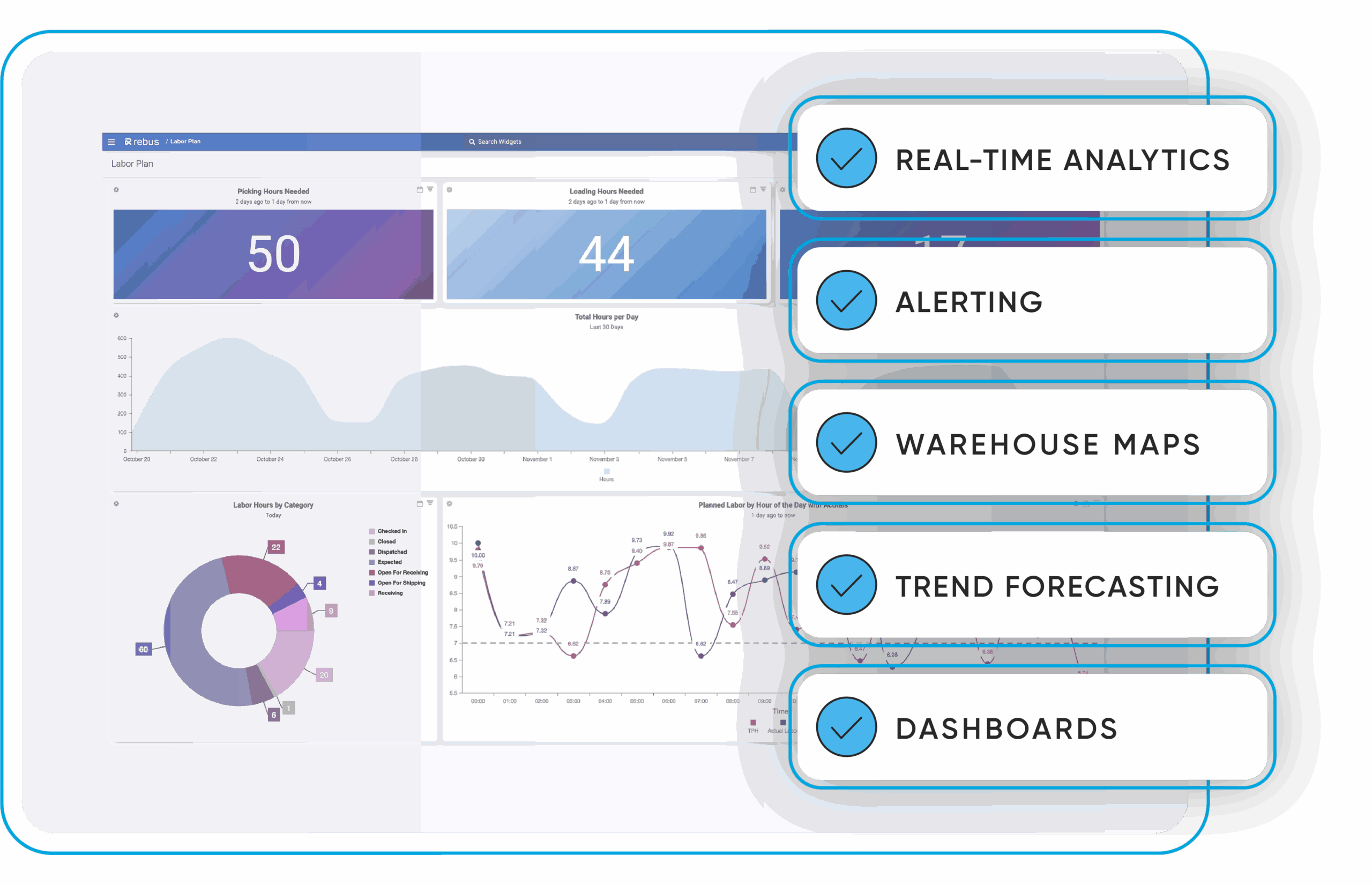

Longbow Advantage is a global leader in supply chain visibility, labor management technology, and Blue Yonder WMS implementation. With a focus on data-driven solutions, Longbow helps organizations optimize warehouse and distribution center operations. Rebus is the company’s advanced analytics platform, integrating real-time data from labor, automation, and inventory to provide actionable insights that enhance decision-making, improve productivity, and reduce costs. Together, Longbow Advantage and Rebus empower businesses with the tools and intelligence needed to achieve operational excellence and drive measurable results.

For more information about Longbow Advantage, visit longbowadvantage.com.

For more information about Rebus, visit rebus.io.

Read the original press release on EINPresswire.

CJ Logistics America Selects Rebus Analytics to Drive Operational Visibility and Efficiency Across Network

MONTREAL, QUEBEC, CANADA | March 5, 2025 — Longbow Advantage, the supply chain technology leader behind Rebus Analytics, is proud to announce that CJ Logistics America, a leading provider of supply chain services to many of the world’s top brands, has chosen Rebus to enhance operational visibility across its extensive network of facilities. Following a rigorous evaluation process searching for a data solution, CJ Logistics found Rebus able to provide the data and reporting it needed.

CJ Logistics undertook a pilot project with Rebus to test the platform’s compatibility with its proprietary warehouse management system. Within a short implementation period, Rebus began capturing and organizing the data critical to operational performance. This pilot, once validated by CJ Logistics’ Operations team, delivered the results they desired, providing value to both employees and customers. Encouraged by this success, CJ Logistics made the decision to deploy Rebus across its network of facilities.

The impact was immediate and measurable for CJ Logistics. A few key savings they found from the Rebus platform include:

- 50% reduction in user location overrides to prior baseline.

- 5% increase in pickline accuracy contributed to a productivity boost and improved service

- Shared visibility between operations and shared services replaced the need for prior reporting tools, simplifying tools and improving efficiency by 3%.

- Rebus further optimized operational efficiency by reducing the time required for refresh runs, resulting in clerical time to focus on critical actions and improvements

With Rebus, CJ Logistics has improved its operational efficiency and visibility. By partnering with Longbow Advantage, CJ Logistics continues to demonstrate its commitment to leveraging cutting-edge technology to drive significant value within its customers’ supply chains.

About Rebus by Longbow Advantage

Longbow Advantage is a global leader in supply chain visibility, labor management technology, and Blue Yonder WMS implementation. With a focus on data-driven solutions, Longbow helps organizations optimize warehouse and distribution center operations. Rebus is the company’s advanced analytics platform, integrating real-time data from labor, automation, and inventory to provide actionable insights that enhance decision-making, improve productivity, and reduce costs. Together, Longbow Advantage and Rebus empower businesses with the tools and intelligence needed to achieve operational excellence and drive measurable results.

About CJ Logistics America

CJ Logistics America provides integrated global supply chain services, maximizing customer value through continuous improvement and innovation. Currently, CJ Logistics America operates technology-driven logistics businesses at 280 locations in 40 countries around the world. With a focus on social responsibility and sustainability through growth with customers and communities, CJ Logistics America prioritizes the well-being of the end consumer. CJ Logistics America offers an integrated, one-stop SCM service platform with air and sea international freight forwarding, warehousing and transportation contract logistics, asset-based trucking, parcel and express delivery, and supply chain consulting. As a lead logistics partner (LLP), third-party logistics provider (3PL) and supply chain consultant, CJ Logistics America helps customers leverage supply chain management as a competitive advantage, reducing total system costs, transforming business processes, improving service and facilitating growth and change.

For more information about Longbow Advantage and Rebus Analytics, visit https://rebus.io/

For more information about CJ Logistics America, visit https://america.cjlogistics.com

Read the original press release on EINPresswire.

Longbow Advantage Announces Ryan Uhlenkamp Appointed as Chief Executive Officer

MONTREAL, QUEBEC, CANADA | February 27, 2025 — Longbow Advantage, the industry-leading supply chain technology company behind Rebus® Analytics and the global leader in warehouse software and consulting, is delighted to announce significant changes in its corporate leadership.

Building on a year of substantial expansion for Longbow Advantage, these strategic changes are expected to help the company meet its growth targets for 2025 and beyond, and continue to provide robust support to customers, ensuring their ongoing satisfaction and success.

Ryan Uhlenkamp steps into the role of CEO, marking a significant and positive milestone in the company’s journey, maintaining stability while advancing opportunities for growth and transformative innovation. With over 20 years in warehousing (including most recently 19 years at Blue Yonder) Ryan has a wealth of knowledge and warehouse optimization expertise. Since joining Longbow Advantage in 2022, and his subsequent promotion to COO in 2023, Ryan has driven impactful growth for the company, establishing and strengthening key customer and partner relationships and enhancing Longbow’s ability to serve the market and meet customer needs with agility and excellence.

Gerry Brady, the company’s founder and current CEO, will transition into the role of Chief Innovation Officer. In this new position he will oversee the Rebus Analytics software development team and help ensure a seamless leadership transition. Brady’s singular focus on pushing future development for Rebus will continue to make it a leader in warehouse analytics and labor management software.

“When I founded Longbow Advantage in 2002, my vision was to create a company that could make a lasting impact. Over the years, we’ve grown into an organization that I’m incredibly proud of,” Gerry Brady said. “Ryan’s leadership, strategic vision, and dedication to our values have been instrumental in our success. As I transition to the role of Chief Innovation Officer, I look forward to continuing to lead the Rebus software development team and supporting Ryan and the leadership team in this exciting new chapter.”

This leadership transition reinforces the company’s commitment to scaling operations, innovating solutions, and delivering exceptional value to all stakeholders.

“I am deeply honored to step into the role of CEO at Longbow,” Ryan Uhlenkamp said. “Since joining in 2022, I have been inspired by the passion, dedication, and talent of our team. I am committed to building on the strong foundation laid by Gerry, driving innovation, and ensuring the continued success of our customers, partners, and employees. Together, we will achieve remarkable growth and create even greater impact.”

With these leadership changes, Longbow Advantage is poised for continued growth and innovation. Under Ryan’s leadership and Gerry’s continued focus on building a best-in-class product, the company remains committed to delivering industry-leading solutions that drive measurable success in warehouse operations.

About Longbow Advantage and Rebus

Longbow Advantage is a global leader in supply chain visibility, labor management technology, and Blue Yonder WMS implementation. With a focus on data-driven solutions, Longbow helps organizations optimize warehouse and distribution center operations. Rebus is the company’s advanced analytics platform, integrating real-time data from labor, automation, and inventory to provide actionable insights that enhance decision-making, improve productivity, and reduce costs. Together, Longbow Advantage and Rebus empower businesses with the tools and intelligence needed to achieve operational excellence and drive measurable results.

For more information about Longbow Advantage, visit longbowadvantage.com

For more information about Rebus Analytics , visit rebus.io

Read the original press release on EINPresswire.